Case Study: Queen's Hospital Romford

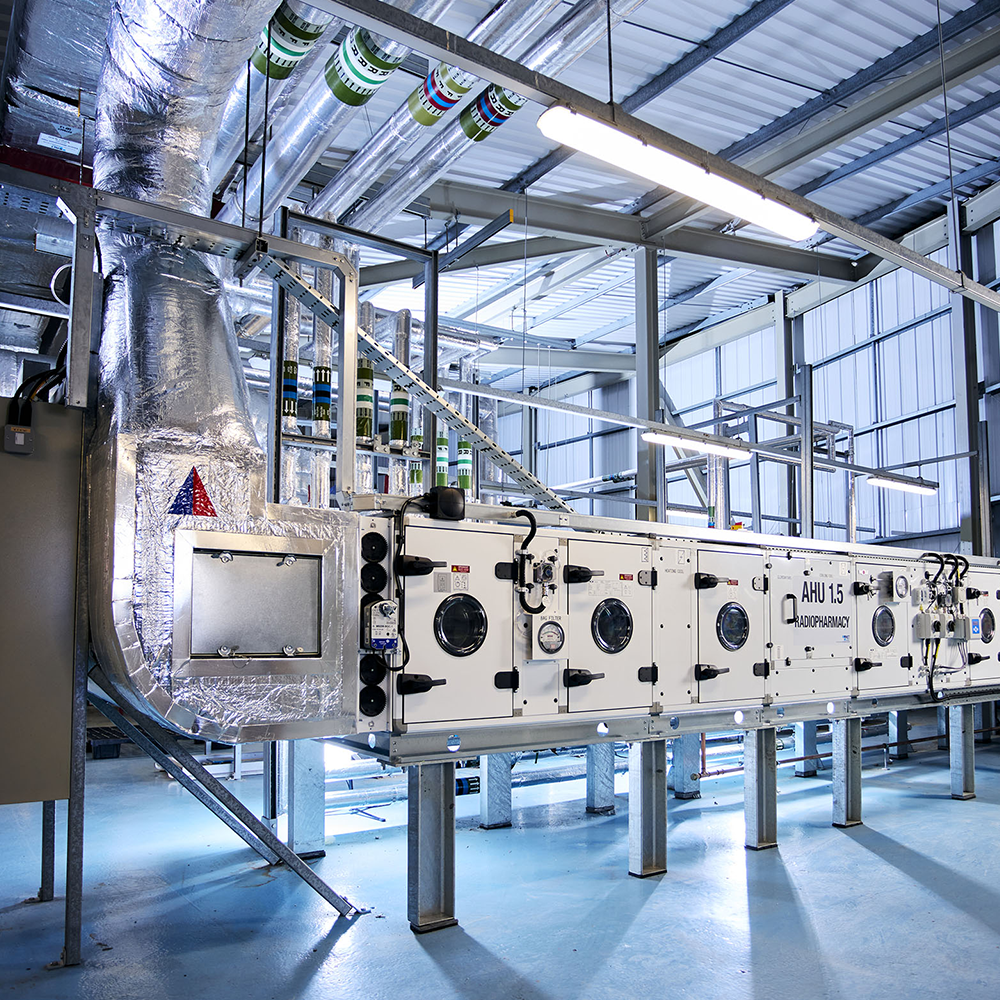

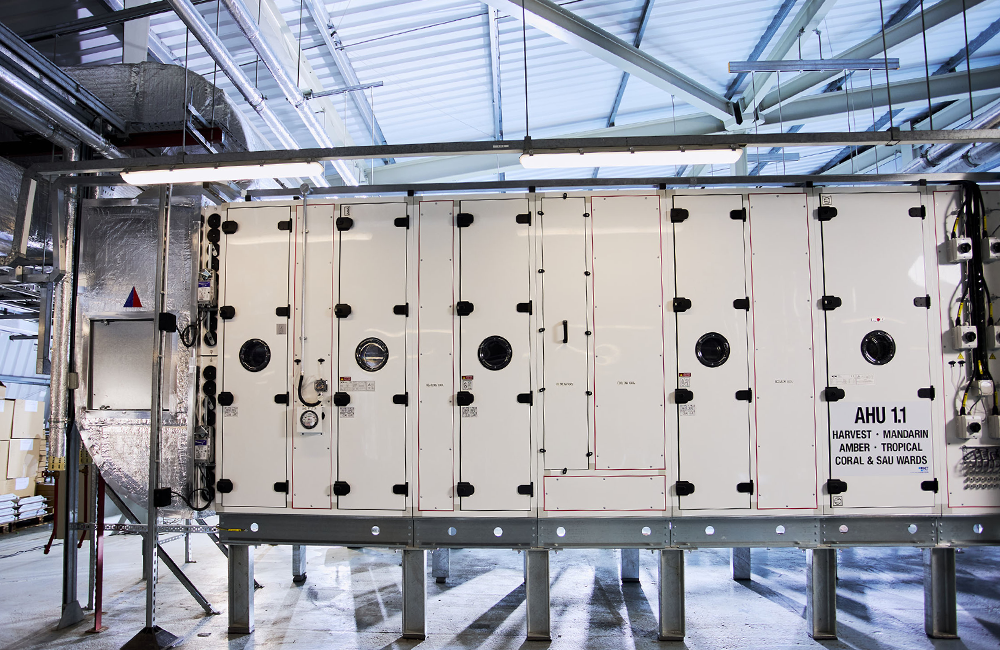

Hospital-Wide AHU Replacement (103 AHUs)

Key Points

Client/Trust: Barking, Havering and Redbridge University Hospitals NHS Trust

Location: Queen's Hospital, Romford

Role & Form: Principal Contractor; Temporary Works Designer; CDM 2015 compliance

Programme: Multi-phase, accelerated programme with clinical continuity maintained

Accreditations: BSA, Constructionline Gold, SafeContractor, NICEIC Approved Electrical Contractor

Demolition & Enabling Works

Safe decommissioning and removal of 103 existing AHUs, ductwork, and associated plant. Comprehensive asbestos surveys and isolations were completed before dismantling. Sequenced crane lifts were managed through detailed lift studies and traffic management, with exclusion zones established around plant areas. Dust and noise were controlled using barriers and HEPA filtration, ensuring no disruption to adjacent wards and theatres.

Structural & Building Works

New plinths, roof penetrations, and steel frameworks were constructed to accommodate modern EC fan-array AHUs. Weatherproofing and fire-stopping reinstatements were undertaken daily, ensuring compliance with Building Regulations and HTM requirements.

Temporary Ventilation Strategy

To maintain continuous operation of critical departments, MET designed and installed temporary AHUs with full filtration, BMS monitoring, and resilience. These were validated to HTM 03-01 by independent Authorising Engineers before switching over, guaranteeing zero unplanned outages during replacement.

Mechanical, Electrical & Specialist Installations

Replacement of 103 AHUs with modern, energy-efficient EC fan array units.

Integration with existing LTHW/CHW systems, ductwork, dampers, controls, and fire interfaces.

NICEIC-certified electrical installation, including new distribution, IPS/UPS, and BMS migration.

Temporary works for crane lifts, gantries, and roof penetrations, all signed off by Temporary Works Engineers.

Quality Management

Project Quality Plan with Inspection & Test Plans (ITPs) for every AHU replacement.

Progressive inspections and witness testing with AE(V).

Material compliance checks (UKCA/CE, DoPs) and certification logs included in O&M manuals.

Quality Management

Project Quality Plan with Inspection & Test Plans (ITPs) for every AHU replacement.

Progressive inspections and witness testing with AE(V).

Material compliance checks (UKCA/CE, DoPs) and certification logs included in O&M manuals.

Environmental Management

Waste management plan achieved >95% diversion from landfill, including recovery of redundant AHUs.

Use of low-VOC materials and adhesives to maintain indoor air quality.

Energy savings from replacing belt-driven AHUs with EC fan arrays, reducing energy consumption by up to 30%.

Sustainable material selection, reducing embodied carbon and lifecycle costs.

Live Clinical Continuity

All critical clinical areas remained live throughout the programme by installing and validating temporary AHUs. During each changeover, ductwork switchover was limited to a maximum of 6 hours, carefully planned and executed to avoid disruption. This ensured Operating Theatres and other critical areas stayed operational at all times during the replacement programme, safeguarding patient safety and providing uninterrupted clinical service delivery.